Normalized Molybdenum Alloyed Rolls

Harder grades have small amounts of carbides in a matrix of normalized fine pearlite. Softer grades have small amounts of Bull's Eyes ferrite. They have a small hardness drop. Their fire cracking resistance is the best among all grades of cast iron rolls. Their tensile strength is comparable to graphite steel or cast steel rolls. These rolls are primarily used for hot rolling applications in roughing and blooming stands. |

|

|

|

|

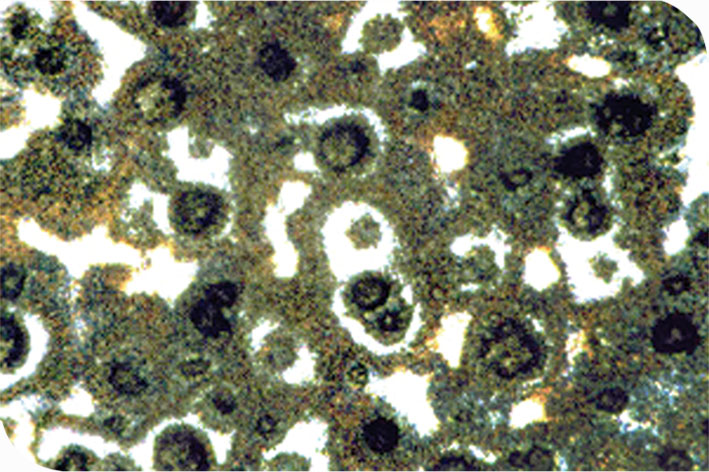

PMoH48N-Pearlitic Matrix with some Carbide(x500) |

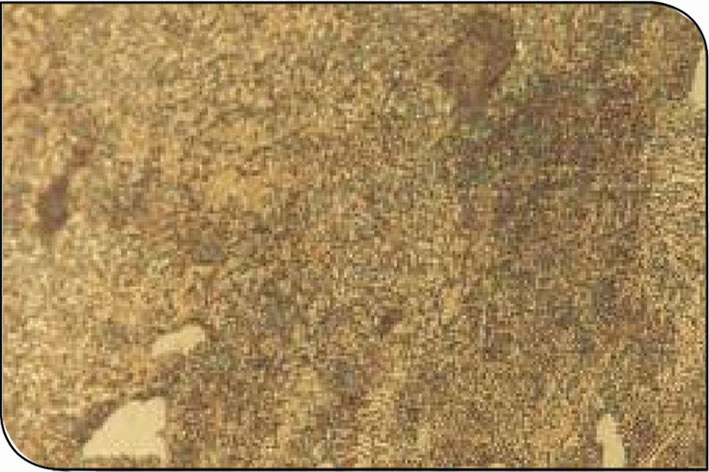

PMoH42N-Pearlitic Matrix with Bull’s Eyes Ferrite and some free Ferrite(x100) |

|

Roll Grade |

Barrels Hardness (ShC) |

C (%) |

Si (%) |

Mn (%) |

Cr (%) |

Ni (%) |

Mo (%) |

Tensile Strength (N/mm2) |

Bending Strength (N/mm2) |

|

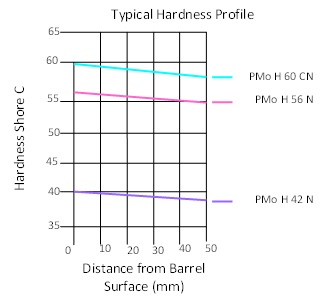

PMo H 42 N |

42 |

3.1-3.5 |

1.6-2.4 |

0.2-0.6 |

0.1-0.4 |

1.5-2.6 |

0.4-0.9 |

600-750 |

900-1400 |

|

PMo H 44 N |

44 |

3.1-3.5 |

1.6-2.4 |

0.2-0.6 |

0.1-0.4 |

1.5-2.6 |

0.4-0.9 |

600-750 |

900-1400 |

|

PMo H 48 N |

48 |

3.1-3.5 |

1.6-2.4 |

0.3-0.8 |

0.1-0.4 |

1.5-2.6 |

0.4-0.9 |

600-750 |

900-1400 |

|

PMo H 52 N |

52 |

3.1-3.5 |

1.2-2.0 |

0.3-0.8 |

0.2-0.8 |

1.6-2.8 |

0.5-1.1 |

600-750 |

800-1200 |

|

PMo H 56 N |

56 |

3.1-3.5 |

1.2-2.0 |

0.4-1.0 |

0.2-0.8 |

1.6-2.8 |

0.5-1.1 |

500-650 |

800-1200 |

|

PMo H 60 N |

60 |

3.1-3.5 |

1.2-2.0 |

0.4-1.0 |

0.4-0.8 |

1.6-3.0 |

0.5-1.1 |

500-650 |

800-1200 |

|

PMo H 56 CN |

56 |

3.1-3.5 |

1.0-2.0 |

0.4-1.0 |

0.4-0.8 |

1.6-2.8 |

0.5-1.1 |

See core Material Info in link1 |

|

|

PMo H 60 CN |

60 |

3.1-3.5 |

1.0-2.0 |

0.4-1.0 |

0.4-0.8 |

1.6-3.0 |

0.5-1.1 |

See core Material Info in link1 |

|

Note: On request, other roll grades not specified in the table can be produced. Cores for compound rolls can be produced with Grey, Compact or Nodular cast iron.